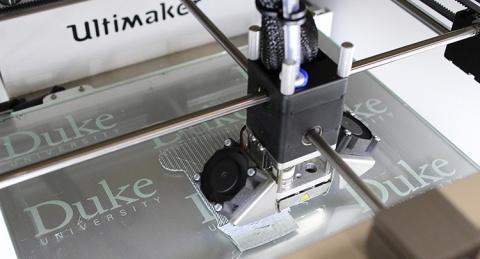

Photo: One of the 80 3D printers in Duke University's Innovation Co-Lab Studio (Credit: Cara O'Malley)

Resident

Using a network of 3D printers in the Innovation Co-Lab Studio at Duke, otolaryngology resident Tawfiq Khoury, MD, creates what was considered impossible just a few years ago. Though 3D printing can be traced to the early 1980s, advancements in recent years have made the technology more affordable and accessible, and therefore more valuable to medicine.

More accurately referred to as additive manufacturing, the process has been used in revolutionary ways, from creating patient-specific models of organs to making implantable substitutes of damaged bone or cartilage for patients who have suffered injury. In Duke’s state-of-the-art 3D printing studio, Dr. Khoury works with other residents, surgeons, and engineers to improve patient care through the use of this constantly evolving technology.

The process of 3D printing involves taking a digital rendering of an object and recreating it one layer at a time out of a given material. Materials range from plastics and metals to what is called bioink, a gelatin substance that can mimic extracellular environments. When infused with cells, this substance can be used to create living tissue. While creating exact models of human organs and tissues out of artificial materials is currently possible, scientists have yet to break the barrier of creating a sustainable duplicate of an organ out of human cells.

As an otolaryngologist, Dr. Khoury works in the 3D studio to recreate the delicate structure of the temporal bones of the ear that can be used for medical training purposes.

“One focus of my research has been taking CT scans of temporal bones, and printing an exact, patient-specific replica,” Dr. Khoury explains. “Our residents can then practice drilling and performing other tests without having to work on an actual patient.”

In the lab, which now holds over 80 3D printers, members from across the Duke community work on a variety of projects. Physicians can use the patient record system Epic to access an ordering system to have models printed in the studio. The system has been used by cardiology, neurosurgery, neurology, and other specialties to create models from CTs, MRIs, and occasionally ultrasound. When these replicas are created for patient care, the lab may be able to provide these services free of charge.

The growth and investment to the facility in 2017 has been extraordinary, Dr. Khoury says.

“With recent renovations, we now have a state-of-the-art facility, with high-end equipment across an entire floor dedicated to the lab.”

As a service to the Duke community, the studio uses 3DPrinterOS, an online cloud management system, to receive requests for prints from anywhere in the world. For those that use the system, a video of the 3D print being created is streamed online.

While the expansion of the facility has opened the door for a larger community of users, it also allows Dr. Khoury to set his sights on some short- and long-term goals. The 3D models created now are extremely accurate and can be used for training purposes, but he feels the technology can be taken one step further. His hope before he finishes his residency is to establish an efficient system to help patients with facial trauma who undergo maxillofacial reconstruction, by routinely creating a perfect 3D-printed model that could eventually be used in implants.

In the future, he is confident that the printers can be used to create organic replacements using hydrogels or bioink. Theoretically, a patient with a damaged eardrum could have an exact model created, infused with living cells, and implanted to restore hearing. While not a possibility today, this type of restorative procedure may be a reality in the near future.

As new uses for 3D printing at Duke are explored, Dr. Khoury feels fortunate to be part of the process.

“The Innovation Lab is a great example of how different departments across the hospital, as well as other healthcare groups, residents, and students, can work together to create something of value for the community.”

The success of the Innovation Studio and its wide application of uses across the hospital show that this could be a model worth reprinting.